Modern repair equipment has revolutionized auto body and collision repair processes, streamlining tasks once manual and time-consuming. This technology, including computer-aided design (CAD) software, laser measurement systems, and robotic arms, enhances precision, speed, and efficiency. Specifically in dent repair, advanced sensors and pneumatic tools save time and ensure minimal disruption to finishes and structures. Ultimately, these innovations reduce service times, boost customer satisfaction, and transform the automotive repair industry for the better.

In today’s digital era, the evolution of repair technology has sparked a revolution in the way we address mechanical faults. The introduction of modern repair equipment has brought about significant advancements, enhancing both accuracy and speed in various industries. This article explores the transformative power of cutting-edge technology, from the leap forward it represents compared to traditional tools to its tangible benefits in precision, efficiency, and cost-effectiveness. Discover how modern repair equipment is redefining the landscape of maintenance across sectors.

- The Evolution of Repair Technology: A Leap Forward with Modern Equipment

- – Exploring the impact of technological advancements on repair processes

- – Comparison between traditional and modern repair tools

The Evolution of Repair Technology: A Leap Forward with Modern Equipment

The evolution of repair technology has brought about a significant leap forward with modern equipment. What was once a manual and time-consuming process in car bodywork and collision repair is now streamlined and precise. Modern repair equipment offers unprecedented levels of accuracy, enabling technicians to make exact measurements and adjustments that were previously unimaginable. This technological advancement not only speeds up the repair process but also enhances the overall quality of work, ensuring that vehicles return to the road looking as good as new.

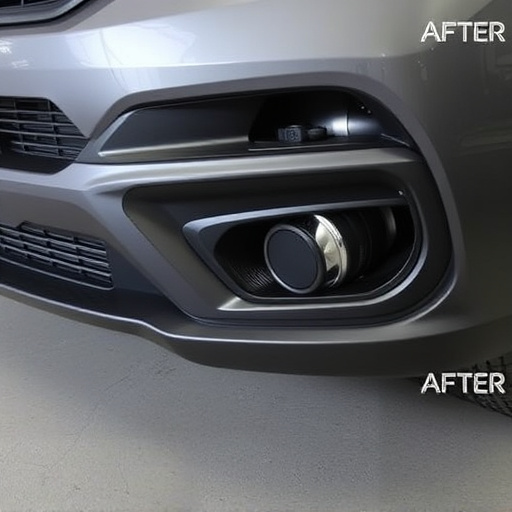

In the realm of auto dent repair, modern equipment has revolutionized the way damages are addressed. From sophisticated sensors that detect even the subtlest of dents to advanced pneumatic tools that effortlessly remove them, these innovations have transformed a tedious task into a swift and efficient one. This not only saves time for both customers and technicians but also contributes to higher satisfaction levels, as vehicles are restored with minimal disruption to their original finish and structure in car collision repair scenarios.

– Exploring the impact of technological advancements on repair processes

In today’s digital era, technological advancements are revolutionizing every sector, and the automotive industry is no exception. Modern repair equipment has emerged as a game-changer, transforming collision repair centers and auto repair shops into highly efficient and precise workshops. These innovative tools and systems offer an array of benefits that significantly enhance the entire vehicle repair process.

With modern equipment, repairs are not just faster but also more accurate. Advanced technologies like computer-aided design (CAD) software, laser measurement systems, and robotic arms enable auto collision centers to complete tasks with remarkable efficiency. For instance, robotic welding can precisely mimic human welders, reducing the risk of errors and ensuring structural integrity. Such advancements streamline workflows, allowing technicians to spend less time on manual labor and more time on complex repairs, ultimately leading to shorter service times without compromising quality in vehicle repair.

– Comparison between traditional and modern repair tools

In the realm of automotive repairs, the evolution from traditional to modern repair equipment has been nothing short of revolutionary. Traditional tools, while functional, often required more time and skill to use effectively. They were limited in their precision and speed, leading to potential errors and prolonged worktimes. For instance, manual dent removal could take hours, leaving visible evidence of the process. In contrast, modern repair equipment offers a multitude of advantages designed to streamline the repair process.

Modern repair equipment, such as advanced dent pullers and paintless dent repair tools, promises unprecedented accuracy and efficiency. These tools are ergonomically designed, reducing the physical strain on technicians, and incorporate sophisticated technology for precise results. For example, computer-aided systems in car body shops can map out damage, ensuring every dent is removed evenly and without leaving marks. Moreover, modern equipment often translates to faster turnaround times, benefiting both repair facilities and their clients, especially in the domain of car collision repair and paintless dent repair.

Modern repair equipment represents a significant leap forward in accuracy and speed, transforming the way we approach repairs. By leveraging advanced technologies, these innovative tools offer unparalleled precision, reducing errors and streamlining workflows. With their efficient designs and intuitive interfaces, modern repair equipment is revolutionizing industries, ensuring faster turnarounds and improved customer satisfaction. Adopting these cutting-edge solutions is not just a trend; it’s a strategic move towards a more robust and competitive service model.