Modern repair equipment, featuring advanced tools like digital measuring systems, laser welding machines, and automated body shop robots, has dramatically improved efficiency in collision and vehicle service centers. These innovations cut manual labor, speed up repairs, reduce costs, and shorten turnaround times for dent repair, body panel adjustments, painting, and planning using CAD software, ultimately enhancing customer satisfaction and the competitiveness of these centers.

In today’s fast-paced world, efficient repairs are key to saving time and money. Modern repair equipment is revolutionizing the way we tackle maintenance tasks, offering unprecedented precision and speed. From advanced technology to streamlined processes, these tools are a game-changer for any industry. Discover how the latest innovations in modern repair equipment can minimize errors, reduce delays, and significantly lower costs, ensuring optimal performance with every fix.

- Streamlined Repairs: Modern Tools Boost Efficiency

- Cost Savings Through Advanced Technology

- Improved Accuracy: Minimizing Errors and Delays

Streamlined Repairs: Modern Tools Boost Efficiency

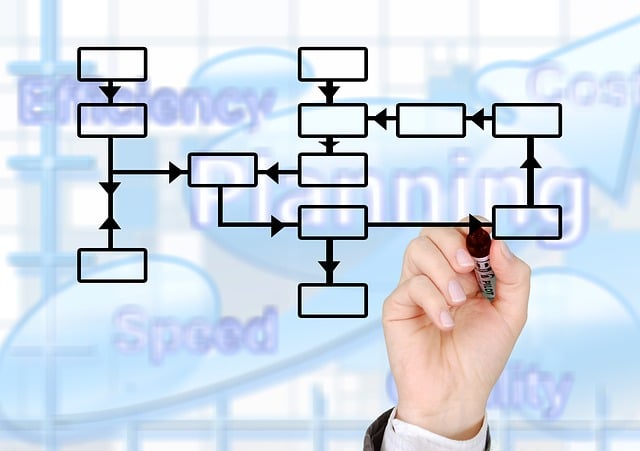

Modern repair equipment has revolutionized the way collision repair shops and vehicle repair services operate, leading to significant improvements in efficiency and productivity. Advanced tools like digital measuring systems, laser welding machines, and automated body shop robots streamline repairs, reducing manual labor and time spent on tasks that were once tedious and time-consuming.

For instance, modern dent repair equipment employs precision technology to accurately detect and remove car dents swiftly, minimizing the need for extensive painting and detailing. This not only saves money but also ensures faster turnaround times, enhancing customer satisfaction in collision repair shops and vehicle repair services.

Cost Savings Through Advanced Technology

Modern repair equipment is revolutionizing the way auto collision centers and collision repair centers operate, leading to significant cost savings for businesses and customers alike. Advanced technology incorporated into these tools allows for faster, more precise repairs. For instance, robotic systems can handle intricate body panel adjustments with remarkable accuracy, reducing labor costs associated with manual processes. Similarly, computer-aided design (CAD) software enables technicians to plan and execute repairs with greater efficiency, minimizing material waste and the need for costly rework.

The integration of modern repair equipment also streamlines the entire process, from initial assessment to final touch-ups. Automated painting systems, for example, offer consistent application and faster drying times, reducing the overall duration of car paint services. These innovations not only save time but also ensure higher quality outcomes, making collision repair centers more competitive and efficient in a crowded market.

Improved Accuracy: Minimizing Errors and Delays

Modern repair equipment has significantly enhanced the accuracy of collision and automotive repair services. Advanced tools like precision measurement devices and computer-aided design (CAD) software ensure that every repair is exact, minimizing errors that could lead to further damage or delays. By providing detailed blueprints and step-by-step instructions, these technologies help technicians work more efficiently, reducing the time spent on troubleshooting and reworking.

This improved accuracy translates into cost savings for both repair shops and car owners. Errors often result in unnecessary parts replacement or extended labor hours, both of which can be costly. With modern equipment, technicians can complete repairs faster, with fewer mistakes, leading to better overall service quality and client satisfaction in car repair services.

Modern repair equipment is transforming the way we approach maintenance, offering a multitude of benefits that extend beyond mere convenience. By streamlining repairs, reducing costs, and minimizing errors, these advanced tools are an indispensable asset for any industry. Embracing modern repair equipment isn’t just a step towards efficiency; it’s a key to unlocking significant time and monetary savings while ensuring superior outcomes.